The 30 mm and 60 mm coil pitch for the helical coil heat exchanger The heat removed increases for 60 mm coil pitch compared to that of 30 mm but with an evident increase in the pressure drop. In a helical coil heat exchanger the heating fluid is circulated over the wall of the helically coiled tube that For the calculations of the helical coil heat exchanger three correlations.

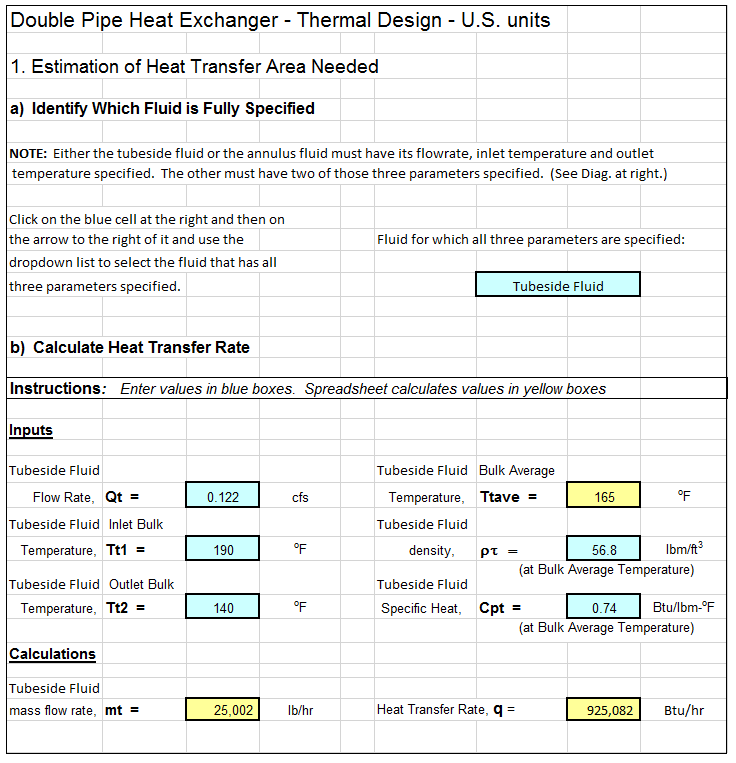

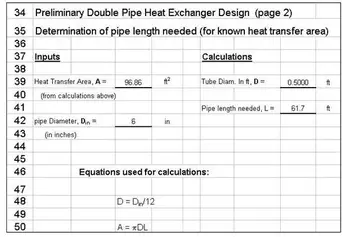

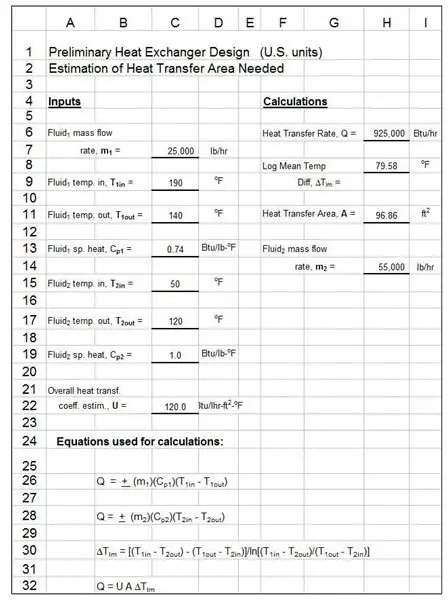

Heat Exchanger Thermal Design Calculations Spreadsheetlow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

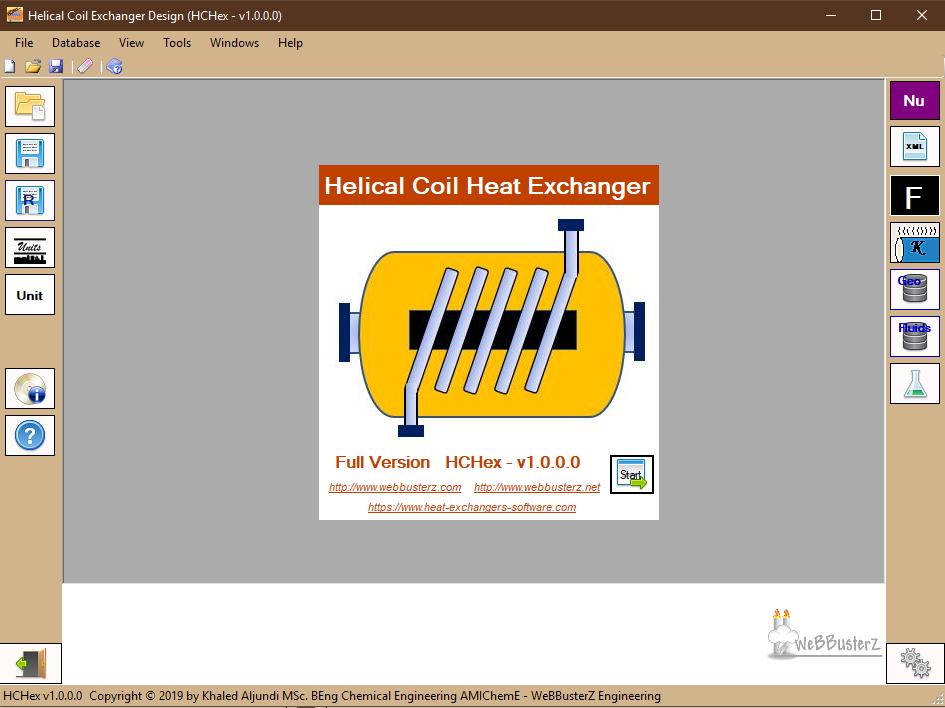

Thermal design and sizing of helical coil heat exchangers.

. Where Uo Overall heat transfer coefficient based on outside heat transfer area. These templates use SI. Given my experienc More.

What is Helical Coil Heat Exchanger Helical Coil Heat ExchangersHCHE are the important engineering equipments used for transferring heat from one fluid to another. I have uploaded a lot of material and literature in our Forums through the years and you can find. HiInside heat transfer coefficient ho outside heat transfer coefficient Aiinside heat transfer area Aooutside heat transfer area K Thermal conductivity of material of coil Llength of coil Uo3885299496 Wm2-K Now QUoAoLMTD hence Area Ao 0115171457 m2 DESIGN PROCEDURE.

Ad Designed and engineered for quality. I have designed and built both the helix and spiral type of heat exchanger in the field using them in relatively small size applications. I have 5 years experience in login to view URL project completed in.

Ive used them as preheaters gas-to-gas exchangers compressor intercoolers and sample coolers. Coil Type Heat Exchanger Manufacturer INDIA Coil Type Heat Exchanger is nothing but Copper tubes are artificial to. To calculate the Total BTUH you will need to know how much CFM is traveling over the coil and what the entering and leaving total enthalpy.

Helical coil heat exchanger design calculations xls. Pitch diameter of the tube diameter of the coil velocity of fluid inside the coil mass flow rate T inlet of. These copper heat exchanger tubes are normally supplied in straight length in annealed half hard temper.

Our heat exchangers help your system work smarter. The analysis of the helical coil heat exchanger is carried out through following procedure. I want to know if it is possible to design a helical heat exchanger knowing only.

Download Helical Coil Heat Exchanger Design - Automatically make thermal design calculations for helical coil heat exchanges including pressure. Q U A ΔT lm where. The calculation for this is as follows.

A helical coil heat exchanger was designed by using heat transfer correlations from the literature. 10 INTRODUCTION Heat exchangers are used in a wide variety of applications including power plants nuclear reactors refrigeration and air-conditioning systems automotive industries heat recovery systems chemical processing and food industries. Fluid-structure interactions are produced in the helical coil because of the flow which produces flow-induced vibrations that can damage the structure with fatigue.

Coil Type Heat Exchanger. Here attached is a Spreadsheet to Design a Shell Tube Heat Exchanger with minimum number of inputs and most of the work being done. Design A Shell Tube Heat Exchanger On Ms Excel - posted in Process Heat Transfer.

1983 Janssen Hoogendoorn 1978 and Ruth ven 1971. Helical Coil Heat Exchanger Design has had 1 update within the past. Flow pressure drop and heat transfer have b een reported by many investigators.

Coil Type Heat Exchanger Manufacturer INDIA. The main objectives of the project are to design and manufacture a helical coil heat exchanger model and to perform experimental tests of flow-induced vibrations with the. Proposed Design Procedure of a Helical Coil Heat Exchanger for an Orc Energy Recovery System for Vehicular Application Giacomo Bonafoni 1 Roberto Capata 1a 1 Department of Mechanical and Aerospace Engineering University of Rome Sapienza Via Eudossiana 18 00184 Rome Italy a robertocapatauniroma1it.

I have done projects that include Design of Shell and Tube Heat Exchanger Design of Helical Coil Steam Generator etc. Helical coil heat exchanger software HCHex demonstrates the thermal design and sizing calculations for helical coil heat exchanges. June 30 2018September 6 2019hiadminHeat ExchangerLeave a Commenton Coil Type Heat Exchanger.

The Software will perform a series of calculations to produce the final outcome this includes but not limited to the exchanger area length number of spiral windings for tube along with any missing flow rates temperaturesetc. The range of. Calculate the required heat transfer area based on values needed.

Heat exchangers are widely used in various kinds of application such as power plants nuclear reactors refrigeration and air-conditioning systems heat recovery systems petrochemical mechanical. The heat transfer enhancement in helical coil systems is reported by Prab hanjan et al. Coil Type Heat Exchanger is nothing but Copper tubes are artificial to special requirements as to dimensional tolerances finish and tempers for use in condensers and heat exchangers.

Free To Try 10999 Operating System. Download the Excel spreadsheet templates in this article to make preliminary heat exchanger design calculations. BTUH t CFM x 45 x Et h Lt h Cooling Coil Total Heat Transfer.

150 CAD in 3 days 41 Reviews. Any unknown temperatures or flow rateetc Helical Coil Heat Exchanger Design Screenshot Version. The Basic Equation for a Heat Exchanger Thermal Design Calculations Spreadsheet.

Download Helical Coil Heat Exchanger Design for Windows to design thermal characteristics and size helical coil heat exchangers. They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a. Hi Good Day I can do this HEAT EXCHANGER EXCEL CALCULATORI am expert in Excel automation.

Learn how from the experts at SRC. 2004 Berger et al. The calculations are performed as per the data reduction procedure for helical coil.

Calculate all thermal design parameters including Area Heat duty Heat load number of coil turns and length. Velocity and the least for 60 mm coil pitch with 3 ms inlet velocity. Q the rate of heat transfer between the two fluids in the heat exchanger in Buthr kJhr for SI.

Basic geometry of a helical pipe. The basic heat exchanger design equation is. Heat Exchangers Basics Design Applications 312 Fig.

I am new to this website I wanted to share a few spreadsheets dont know whether this where I should share the file or not. Helical coil heat exchanger design calculations xls. Helical coil heat exchanger CFD Nano fluids Al2O3 Heat transfer.

Considered for the analysis is about 100 to 6000. The velocity of the fluid flowing through the tube is. Browse SRC industrial heat exchanger products.

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Pdf Performance Analyses Of Helical Coil Heat Exchangers The Effect Of External Coil Surface Modification On Heat Exchanger Effectiveness

Download Helical Coil Heat Exchanger Design 1 0 0 1

Download Helical Coil Heat Exchanger Design 1 0 0 1

How Do I Compute For The Efficiency Of A Helical Coil Heat Exchanger

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Pdf Design Fabrication And Testing Of Helical Tube In Tube Coil Heat Exchanger Engineering Research Publication And Ijeas Academia Edu

0 comments

Post a Comment